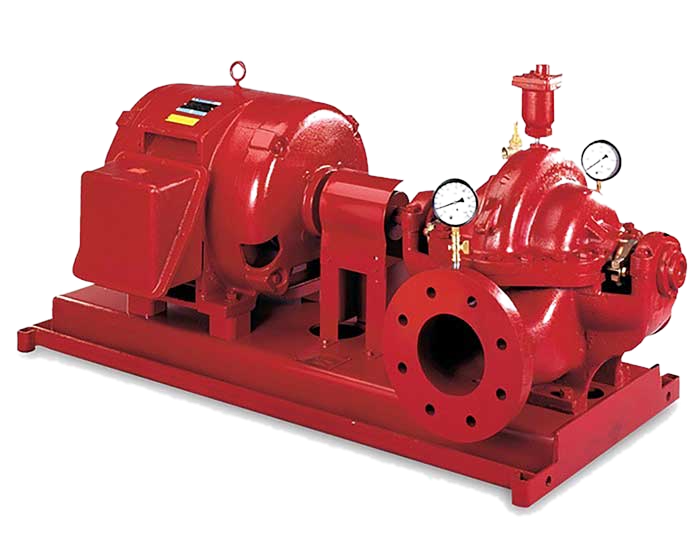

Fire pumps are used to force water through a sprinkler system up to many building floors, such as a hotel or convention center. These pumps must be strong enough to push water against gravity as the water travels up floor after floor to pressurize the sprinkler lines.

Buildings that exceed 500 feet in height are often beyond the capacity of most pumps on the market. Fire pumps are the main component behind any water-based fire protection system. It is vital that these pumps are designed and installed properly; otherwise, the fire protection system may not function as originally through and designed to.

The reliability of fire pumps is nowhere more mission-critical than in your high-rise buildings. In most highrise buildings an evacuation of the building occupants during a fire may not always be feasible.

The 2016 the NFPA released new rules that specifically address fire pumps that are installed in high-rise buildings, with the intent of standardizing how fire systems in high rise are created to ensure an appropriate level of reliability no matter how tall the building is.

The NFPA 20 Technical Committee developed specific provisions regarding these fire pumps and how they move water. Under the new requirements, even if one piece of equipment becomes impaired, the whole system will not be affected. With these new rules in place, the full protection of the building can still be met even if a pump goes down.

One of the most major changes in fire pump building design for high-rise buildings is that fire pumps operating in a series can no longer have the pumps on different floors unless some very stringent criteria are met to demonstrate a failsafe is met to ensure safe operation of all pumps. This is called the practice of vertical staging — placing the second and third fire pumps in series and assigning them to a set number of floors. Consequently, if the first fire pump fails, the rest of the fire pumps in series after that one will also fail for lack of adequate suction pressure.

It’s simple; they use a series of pumps, this is known as vertical staging. In this process, all the water for the building travels from one pump to another in a chain fashion. Each fire pump is labeled for the number of floors its responsible for.

Having a system like this is the only way to push water floor after floor up, but this also means that maintaining the pumps is vital in saving lives. If a fire started on the first floor, the first-floor pumps would go off to help extinguish the fire.

Now let’s say the fire started on the 49th floor; this means the first pump would go off to push water to the 2nd pump, and from the 2nd to the 3rd, etc till it reaches the pump that handles that floor. This is done so there is not too much pressure put on anyone pump that would cause it to burn out.

Not all fire pumps are created the same.

Fire pumps are made from all different material types depending on the designed application usage. For pumps that need to be lightweight, they would often be made up from an anodizing high strength aluminum alloy.

This would create a lightweight, durable fire pump resistant to most corrosion and wear types. Anodizing may be more expensive but is worth it when working with these types of softer materials.

If strength is the primary focus, then you will find them made from ductile or cast iron. Both of these will deliver the power required to pass a maximum of 500 psi.

The pump’s main function during the pumping process is an essential part of all. The impeller shaft is designed to move all of the water into the pump’s body; this causes the pump to build pressure inside and forces the water to the passageways that are required to deliver water to the supply lines. Doing this allows the pumps to direct the wet stuff to the red stuff.

There are also what are called two-stage fire pumps. These are designed to offer a broader operating range for optimal performance when working in the parallel mode, mainly intended for the series mode for lower flows at or higher pressures.

Final Thoughts

Most fire pump-related parts tend to need servicing and replacements over time as use, abuse, and other such factors will cause them to weaken, leak or just not work as intended. Yes, they are built to resist plenty of corrosion in their long term use, but that does not make them immune to eventual wear and tear, much more the regular need for maintenance and inspections.

Ensure your fire pump is both up to standard and ready to roll for when you need it. No emergency will ever allow you sufficient time to look into it without being prepared beforehand. Be prepared for when the need arises.