A fire pump system is a critical component in many industrial facilities’ fire protection strategies. Whether you’re managing a processing plant, warehouse, manufacturing site, or high‑rise facility, understanding how a fire pump system works, how it’s maintained, and how to stay compliant with safety standards can save lives — and protect your assets. In this guide, we’ll walk through the basics, regulatory and compliance considerations, testing and maintenance, and how proper system selection and care improve overall safety.

What Is a Fire Pump System and Why It Matters

It is designed to increase water pressure in a fire protection network when the existing supply cannot meet the hydraulic requirements of sprinklers and standpipe systems. Fire pumps are typically integrated into larger water‑based fire protection systems to ensure that, during an emergency, water pressure remains adequate to control or suppress fires. This is essential where municipal water pressure is insufficient due to building height, remote locations, or high demand at multiple outlets simultaneously.

Core components include:

- Pump – moves water into the system

- Driver – often an electric motor or diesel engine

- Controller – activates the system when pressure drops

Once a drop in pressure is detected (such as from an open sprinkler head), the controller automatically starts the pump to maintain necessary flow and pressure.

Regulatory Considerations: Codes and Standards

Design, installation, and maintenance of a fire pump system are governed by recognized safety codes, most notably NFPA 20: Standard for the Installation of Stationary Pumps for Fire Protection. NFPA 20 outlines how fire pump systems must be sized, installed, and tested to ensure reliable performance.

In addition to NFPA 20, related regulations (such as local building codes and the International Building Code) may apply to the placement and protection of fire pump rooms, clearances, electrical supplies, and access. These codes help ensure that they continue operating under emergency conditions, which can include exposure to fire, water, or other hazards.

Compliance isn’t just about meeting minimum regulations — it’s about safeguarding your people, your facility, and your business continuity. A compliant system is more likely to perform when needed and may also positively influence insurance ratings and risk assessments.

Choosing the Right Fire Pump System

The right system depends on your facility’s size, water supply, and safety demands. Outlook Enterprises simplifies that choice with:

- Multiple configurations: Horizontal split case, vertical inline, or vertical turbine

- Power options: Electric motors for efficiency, diesel for backup—or both for redundancy

- Same-day access to full pump units, motors, rotating assemblies, and more

We also stock critical fire pump components like:

- Case gaskets, packing glands, and braided packing

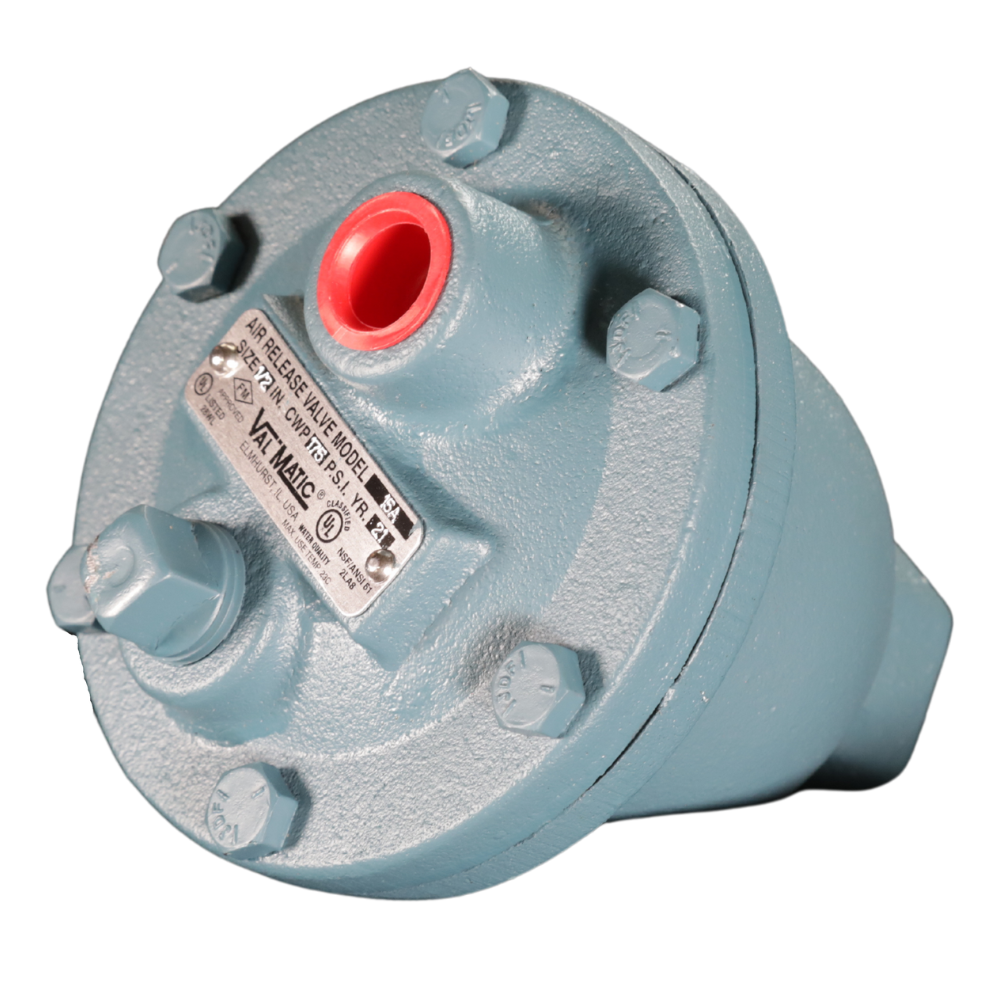

- Relief valves and CLA-VAL pressure control valves

- Winter pressure gauges, lantern rings, and removal tools

Our inventory supports brands like Allis Chalmers, Peerless, and Aurora. Whether replacing parts or installing a full unit, Outlook helps you stay compliant and prepared.

Regular Testing and Maintenance: Keeping Your System Ready

A fire pump system must not only be correctly installed but also regularly tested and maintained. Industry standards recommend:

- Weekly testing to verify basic operation

- Monthly inspections of gauges, valves, and packing to catch early wear

- Annual comprehensive maintenance including flow or performance tests

These practices ensure that it operates as designed and can handle the demand during an emergency. Regular maintenance also helps extend the service life of system components like gaskets, packing, relief valves, and pressure gauges.

Outlook Enterprises stocks key fire pump components — from packing kits and relief valves to complete pump units — and can support your maintenance planning by providing quality parts or expert recommendations.

Ensuring Long-Term Reliability and Safety

A reliable fire pump system is a cornerstone of an industrial facility’s life safety and property protection strategy. Understanding the basics of how they work, how to choose the right configuration, and how to conduct regular testing and maintenance will help ensure your systems perform when they matter most.

Outlook Enterprises can help you source quality fire pumps and parts — including complete units, packing kits, pressure gauges, and relief valves — and support you with recommendations that match your facility’s needs. Whether you’re planning a new installation or maintaining existing equipment, proactive decisions today can help protect your operation tomorrow.